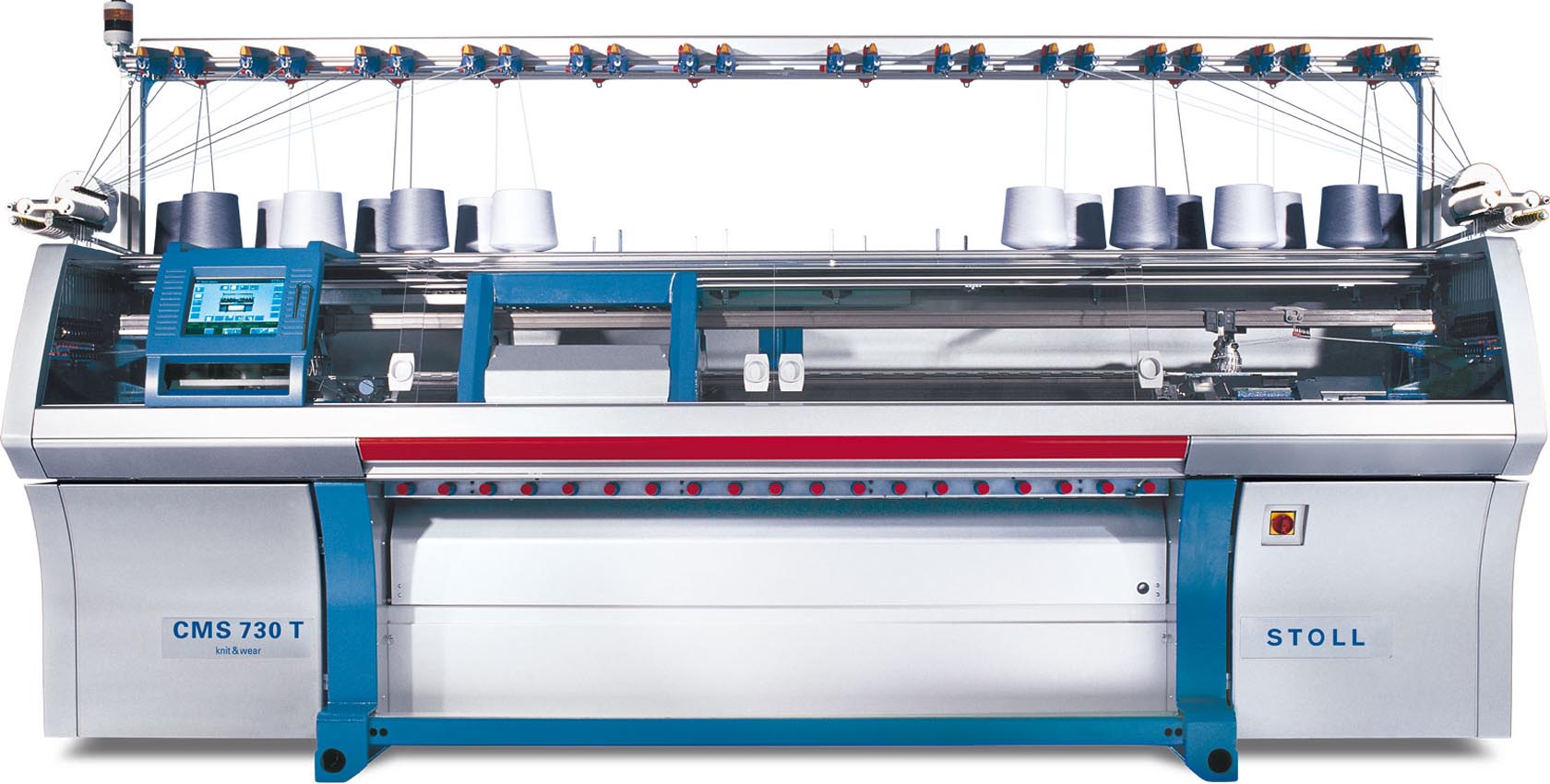

Our Infrastructure

Infrastructure and List of a Few Clients

The credit for our success goes to our dedicated and diligent work force, coupled with a highly strong and sound infrastructure.

Our Production systems are highly organized, to the last detail. Each of the manufacturing units is specialized, product-wise. State-of-the-art machines enhance productivity and maintain consistent quality standards.

Our factories have their own inbuilt stores for fabric and accessories which enables them to handle all necessary details required to complete one particular order at a time. Our production facilities are totally integrated to facilitate all the process involved in garment manufacturing in-house, be it fabric cutting, fusing, finishing or packing.

Our production facilities are fully equipped with sophisticated computerized spreading machines. These machines ensure that fabrics are spread evenly by way of tension and width. By doing so, maximum usage of complete fabric width is ensured, thereby optimizing consumption, minimizing wastage and saving of time.

Finishing process

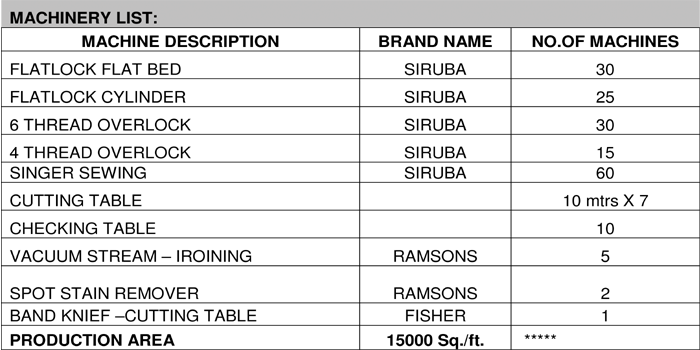

KNITTING

Rib pointed jacquard.

Interlock.

Mini Jacquard.

Rib & Interlock.

Single Jersey.

Three Thread Fleece.

P.K. Fleece.

Heavy Jersey.

WELLKNIT, HK – 3 tone / day

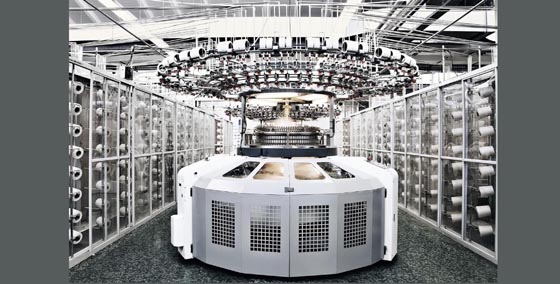

FLAT KNITTING

KH Fully Computerized Machine.

KH Computerized – Birds eyeDesign Machine.

MAT Automatic CK 4 Colours Machine.

Pain Production 2000 pcs / Day,

Design production 1500 pcs / Day,

TABEL PRINTING

Our printing is specialized for

Pigment and foam,

Plastizol and tie-dye,.

High Density and Glitter,

Foam and Spray,

Discharge and Transfer Foil Prints ETC .

I&M, Production 5000 pcs / Day.

Finishing and Testing

EMBROIDERY

Computer Embroidery Machines with 9 Colour and 20 heads with special

Features of Sequins, Cording, Looping & boring.

Basic design 7000 pcs / Day,

Appliqué design 3500 pcs / Day.

MACHINE PRINTING

Screen Printing

12colours chest printing M/c.

We can do all type of prints,

Production basic 5000 pcs / day,

Production fashion 3000 pcs / day,

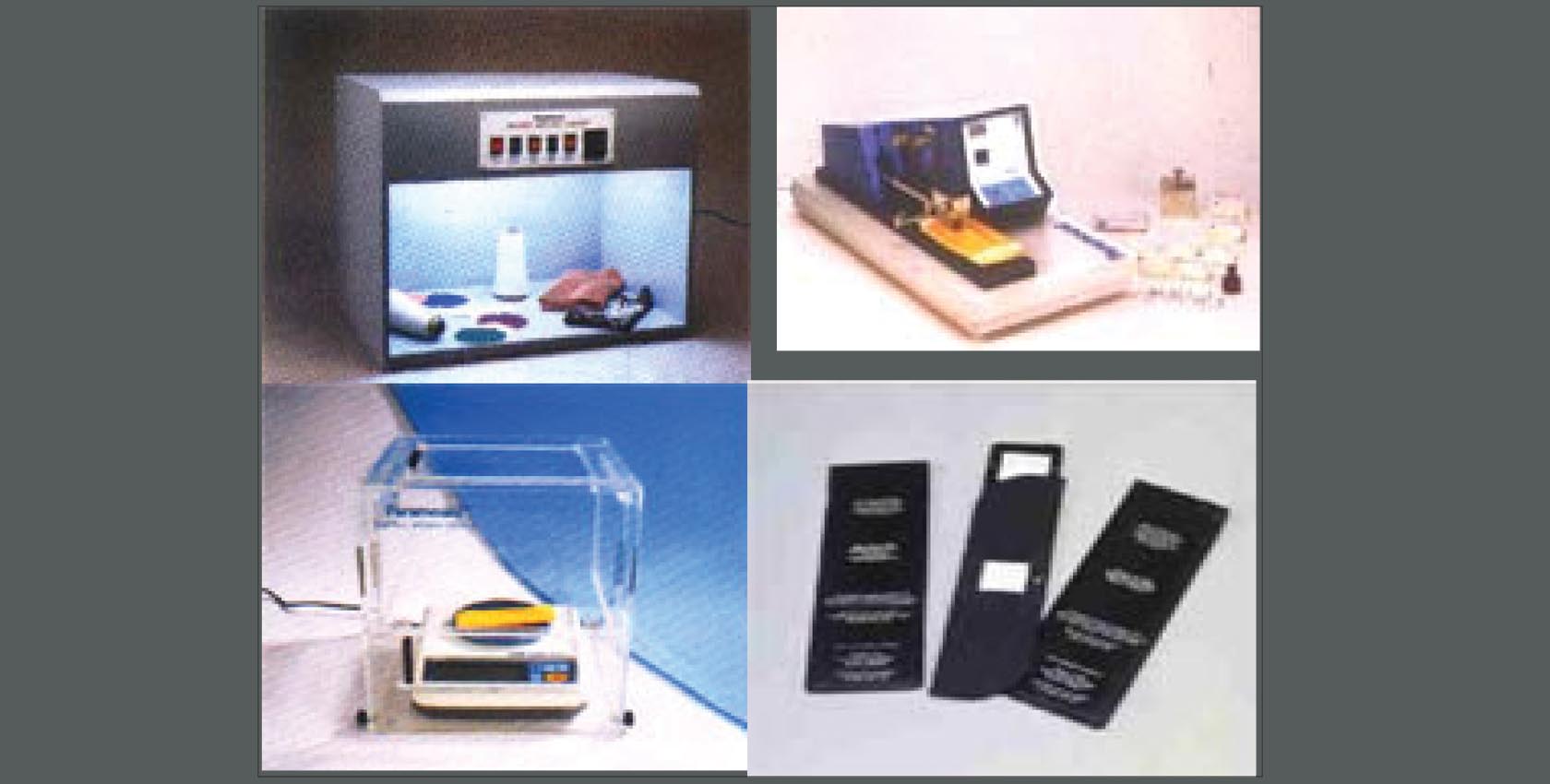

LAB EQUIPMENTS

COLOUR MATCHING CABINET.

CROCK METER.

LAUNDERO METER.

WASHING MACHINE.

GSM SCALE.

GREY SCALE FOR STAINING & SHADING.

YARN COUNT PILLING TESTER